You can make reusable energy that’s kind to the planet!

Bio Diesel Fuel Refining System

– Carbon Neutral Fuel –

What is Bio Diesel Fuel

Biodiesel fuel is a generic term for oil derived from plants such as rapeseed oil, sunflower oil, soybean oil, corn oil, etc., whether used or unused, that is recycled into diesel engine fuel.

Because the raw material is vegetable oil, even if CO2 is emitted by combustion, the total amount of CO2 in the atmosphere does not increase.

CO2 emissions are considered zero (0).

Compared to conventional diesel oil, it has the advantage of emitting almost no sulfur oxides (Sox). It is an environmentally friendly fuel.

Why Biodiesel fuel is not widely used 1

Conventional biodiesel refining methods generate large amounts of polluted water in the process, which is a major environmental burden.

Requires large sewage treatment facilities

Why Biodiesel fuel is not widely used 2

Conventional biodiesel refining methods do not stabilize the performance of the resulting fuel. Also, the degree of purification is low because impurities in the feedstock cannot be removed.

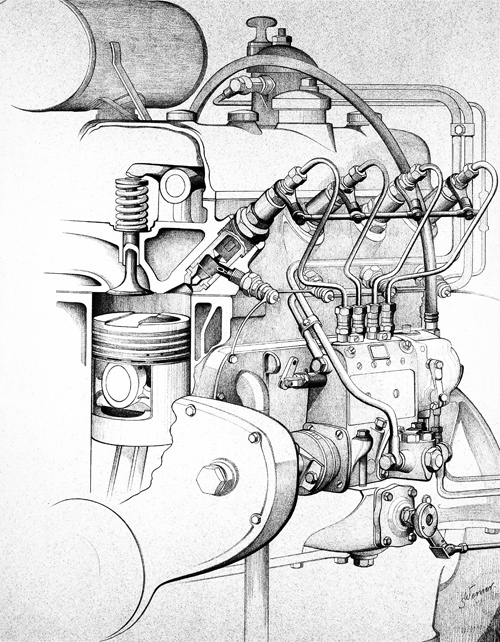

It can run a simple engine, but not for stable diesel power generation or common rail compliant diesel engines.

Alcedo’s Bio-diesel fuel refineries have solved all of these problems!

Polluted Water → Not Generated!

Sewage Treatment Facility → Doesn’t Need it!

Power generation efficiency → High Efficiency!

Use in diesel engine vehicles, ships,

and agricultural equipment → No Problem

Patent No. 5185696 (Japan)

Bio-Diesel Fuel Refine System

Our BDK series biodiesel fuel refiner is the ideal form of refining equipment that solves problems such as the treatment of wash water in conventional refining methods.

The BDK series employs a new distillation method, developed jointly with Associate Professor Tatsuro Kijima of the Yamagata University Graduate School.

The BDK series eliminates the water washing process, which has been difficult to achieve with conventional methods, and enables the refining of high-purity biodiesel fuel, thereby completely solving the quality problems with conventional methods. This refinery achieves stable and high quality that exceeds the standards of JIS, EU, and USA.

Refined BDF is supplied to diesel engine vehicles and generators after filtering out impurities that may cause vehicle malfunctions, using a refueling pump with a 20L filter.

Component analysis of Alcedo’ Bio-Diesel

| Item | EU spec | MSD Bio Diesel | ||

| 1 | Water | 500ppm or under | 160ppm | |

| 2 | 10% carbon Residue | 0.3% or under | 0.09% | These items can be a cause of engine failure |

| 3 | Total Amount of Glycerin | 0.25% or under | 0.02% | ” |

| 4 | Triglyceride | 0.2% or under | Less than 0.01% | ” |

| 5 | Diglyceride | 0.2% or under | Less than 0.01% | ” |

| 6 | Monoglyceride | 0.8% or under | Less than 0.01% | ” |

| 7 | Free Glycerol | 0.02% or under | 0.01% | ” |

| 8 | Amount of Ester | 96.5% or under | 99.9% | Higher Value is better |

Output Calculation

•Processing 200L of waste food oil

•High Quality Bio Diesel = 140L (65% – 75% depends on quality of the material)

•99.9% Very Pure Glycerin = 18L (30% of Crude Glycerin)

•A Heavy Oil = 18L (30% of Crude Glycerin)

•Waste = 24L (40% of Crude Glycerin)

•Require 18L of Methanol for synthesis but 4L of it can be regained.

•Total Synthesis time : 8 Hours

Technology for refining high-purity

Glycerin from crude Glycerin

Producing High Value-added products from unneeded discarded materials

New Energy Venture Technology Innovation Adopted Project in 2010

Research and development on resource recovery of unused by products in BDF synthesis

Corporate Brief

•Name:Alcedo Inc.

•Location: 3-2-6m Shin-Yokohama, Kohoku-Ku,Yokohama, Kanagawa 222-0033

•Established: 25th of July, 2018

•CEO:Naoki Kawahara

•Web Site: www.alcedo.co.jp